In nowadays commercial and electric sectors, coating technologies are more than only a relay of surface attraction—they outline durability, reliability, and general performance. Among all of the options available, vacuum metallizing has risen to the pinnacle because the gold is stylish in modern-day-day coatings.

I’ve personally seen how conventional coatings every now and then fail beneath stress. Paint may additionally peel, electroplated layers also can corrode, and sprayed finishes often lose their luster too quickly. But vacuum metallization offers a consistent, smooth, and strong end that meets the high expectations of industries internationally.

Understanding the Process

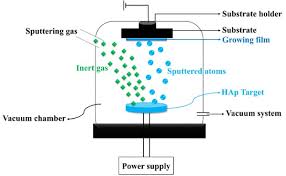

So, what makes vacuum metallization so particular? The method takes the region inside a vacuum chamber in which a thin metal—normally aluminum—is vaporized. Once vaporized, the steel bonds gently to the substrate, growing a uniform, reflective coating.

The science is elegant yet powerful. This extraordinarily-skinny metallic layer enhances appearance while moreover imparting resistance to moisture, wear, and corrosion. The end isn’t simplest, clean and present day however additionally functionally superior to many traditional strategies.

Why Industries Depend on Vacuum Metallizing

From my professional revel in, vacuum metallizing maintains to show its worth because it offers a definitely ideal blend of aesthetics and normal overall performance. Its key advantages consist of:

Durability under tough situations – Resistant to scratches, chemicals, and environmental strain.

Lightweight design – Adds nearly no weight, this is vital in electronics and packaging.

Eco-friendliness – Unlike electroplating, it avoids dangerous chemical compounds and decreases waste.

Consistency – Every layer is calmly implemented, making sure reliable and repeatable outcomes.

This mixture of advantages explains why industries as numerous as car, aerospace, packaging, and electronics have embraced it as their desired coating answer.

The Role of Metallized PET Film

A fine instance of metallization at artwork is metallized PET film. This material is created with the aid of applying a thin aluminum layer to PET (polyethylene terephthalate) film. The result is a lightweight, robust, and distinctly bendy product.

I’ve labored with metallized PET film throughout one-of-a-kind applications, and it always presents incredible results:

Electrical protecting – Provides EMI and RFI protection for sensitive electronics.

Packaging packages – Extends product shelf lifestyles with the resource of blocking off moisture and oxygen.

Industrial laminates and tapes – Adds power, flexibility, and safety in demanding environments.

Its stability of charge-effectiveness and overall performance makes metallized PET film pass-to answer for mass manufacturers.

Why Choose Shieldingtape.Com?

When agencies invest in metallizing solutions, reliability and belief are non-negotiable. That’s where Shieldingtape.Com stands out.

Proven knowledge: Years of revel in industrial coatings suggest we know a way to fulfill practical worrying conditions.

High-exceptional merchandise: From vacuum metallizing to metallized PET film, our products are tested for sturdiness and precision

Transparent provider: We pay attention to the building receive as authentic with clean specifications, reliable help, and aggressive pricing.

Our clients price us due to the fact they realise they’re operating with a company who’s familiar with each of the technological information and the realistic application of coatings.

Looking Ahead: The Future of Coatings

As industries demand extra sustainable and excessive-typical performance solutions, vacuum metallizing will continue to conform. New enhancements are already making the manner greater power-green whilst improving adhesion and durability. From renewable energy to advanced electronics, its destiny packages are giant.

Final Thoughts

Vacuum metallizing has earned its reputation because it is gold trendy because it does greater than create a sparkly surface. It gives lengthy-lasting power, uniformity, and environmental blessings that contemporary industries call for.

By embracing answers like vacuum metallization and revolutionary substances including metallized PET film, agencies advantage coatings which might be each visually placing and technically advanced.

At Shieldingtape.Com, we take satisfaction in turning in products that combine technological knowledge, functionality, and accept as true with—finishes and movies that actually live as a whole lot because the gold stylish in current-day coatings.