When it comes to protecting electrical components, NEMA enclosures play a vital role. These enclosures are designed according to the standards set by the National Electrical Manufacturers Association (NEMA) and ensure safety, durability, and reliability for electrical systems in different environments. Whether installed indoors or outdoors, choosing the right NEMA Enclosure type can make all the difference in performance and safety.

This article breaks down the different types of NEMA enclosures, their specific ratings, and how they are used for both indoor and outdoor applications.

What Is a NEMA Enclosure?

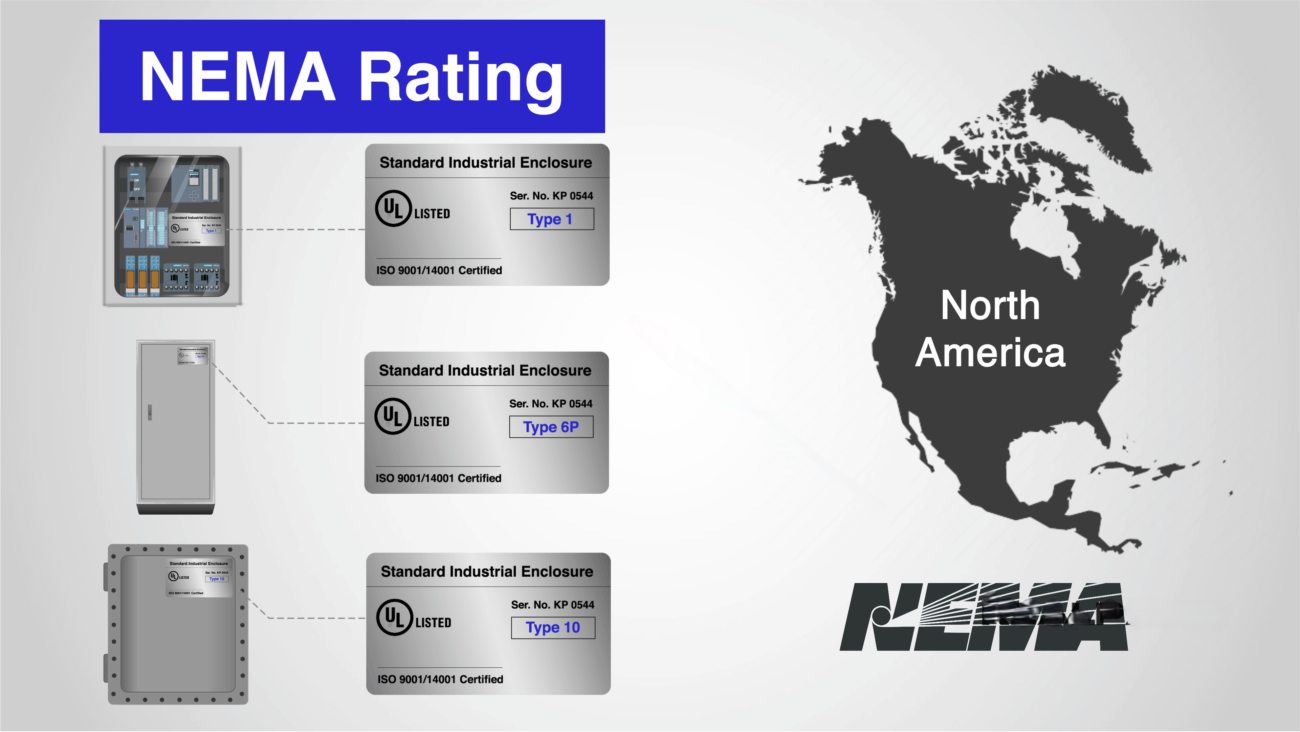

A NEMA enclosure is a cabinet, box, or housing that protects electrical equipment from environmental hazards such as dust, water, corrosion, and accidental contact. Each NEMA type has a rating that specifies the level of protection it provides. Unlike IP ratings (Ingress Protection), which are international, NEMA standards are widely used in North America.

For engineers, contractors, and facility managers, understanding these ratings ensures that the right enclosure is chosen for the job.

Why NEMA Ratings Matter

NEMA ratings matter because they:

- Protect equipment – from moisture, dust, or other external factors.

- Ensure safety – by preventing accidental contact with live electrical parts.

- Extend equipment lifespan – by reducing wear and tear caused by environmental conditions.

- Meet compliance requirements – for safety standards in industrial and commercial settings.

By selecting the right enclosure, costly downtime and equipment damage can be avoided.

NEMA Enclosure Types for Indoor Use

Indoor environments may seem safer than outdoor ones, but electrical systems are still exposed to hazards like dust, dripping water, and accidental contact. NEMA enclosures designed for indoor use are built to address these challenges.

NEMA 1

- Protection Level: Basic protection against dust and light contact.

- Common Uses: Control panels, junction boxes, and indoor wiring closets.

- Application: Suitable for offices, schools, or indoor facilities where environmental hazards are minimal.

NEMA 2

- Protection Level: Adds protection against light dripping water.

- Common Uses: Light manufacturing areas, machine rooms, or laundry facilities.

- Application: Where occasional moisture or condensation may occur indoors.

NEMA 12 & 12K

- Protection Level: Protection against dust, dirt, and dripping water.

- Common Uses: Industrial plants, factories, or workshops.

- Application: Ideal for manufacturing areas with oil drips, dust, and debris.

- NEMA 12K: Includes knockouts for easier conduit installation.

NEMA 13

- Protection Level: Protects against dust, spraying water, and oil.

- Common Uses: Food processing plants, chemical labs, and manufacturing spaces.

- Application: When additional protection against oil and coolant splashes is needed.

NEMA Enclosure Types for Outdoor Use

Outdoor environments pose more serious threats such as rain, snow, corrosion, and even submersion in water. NEMA outdoor enclosures are built with stronger materials and advanced sealing techniques to withstand these conditions.

NEMA 3, 3R, 3S

- Protection Level: Protects against rain, snow, and sleet.

- Common Uses: Utility boxes, telecommunications cabinets, outdoor panels.

- Application: Standard outdoor settings such as parking lots or building exteriors.

- NEMA 3R: Improved drainage and weather protection.

- NEMA 3S: Ensures mechanisms remain operable when covered in ice.

NEMA 4 & 4X

- Protection Level: Protects against splashing water, hose-directed water, and windblown dust.

- NEMA 4X: Adds resistance to corrosion.

- Common Uses: Food and beverage plants, outdoor control stations, marine environments.

- Application: Widely used outdoors in areas exposed to washdowns, rain, or saltwater.

NEMA 6 & 6P

- Protection Level: Protects against temporary or prolonged submersion in water.

- Common Uses: Underground installations, wastewater facilities, or outdoor electrical vaults.

- Application: Areas prone to flooding or heavy water exposure.

NEMA 7, 8, 9, and 10 (Hazardous Locations)

- Protection Level: Designed for environments with explosive gases, dust, or hazardous materials.

- Common Uses: Oil refineries, chemical plants, mining operations.

- Application: Only for classified hazardous environments.

Comparing Indoor vs. Outdoor NEMA Enclosures

| Feature | Indoor Enclosures | Outdoor Enclosures |

| Protection | Dust, dirt, accidental contact, occasional drips | Rain, snow, corrosion, submersion, ice |

| Common Types | NEMA 1, 2, 12, 13 | NEMA 3, 3R, 4, 4X, 6, 6P |

| Typical Use | Offices, factories, labs, workshops | Utility boxes, marine areas, industrial plants |

| Material | Often steel or plastic | Stainless steel, aluminum, fiberglass |

Choosing the Right NEMA Enclosure

Selecting the right enclosure depends on the following factors:

- Environment – Is it indoors or outdoors? Will it face water, dust, or chemicals?

- Equipment sensitivity – How critical is the equipment inside?

- Maintenance access – Does it need knockouts or corrosion resistance?

- Budget – Higher protection levels usually cost more.

For example:

- A NEMA 1 enclosure is fine for an office environment.

- A NEMA 4X enclosure is essential for a food plant requiring regular washdowns.

- A NEMA 6P enclosure is best for underwater or flood-prone areas.

Common Applications of NEMA Enclosures

Industrial Settings

Manufacturing plants rely on NEMA 12 and NEMA 13 enclosures to protect machinery control systems from dust, oil, and coolant.

Commercial Buildings

Offices and schools often use NEMA 1 enclosures to protect electrical wiring and circuit breakers in secure rooms.

Outdoor Utilities

Power distribution panels and telecom cabinets use NEMA 3R or NEMA 4 enclosures to endure weather exposure.

Marine and Coastal Areas

Saltwater environments demand corrosion-resistant NEMA 4X enclosures for durability.

Hazardous Environments

Oil refineries and chemical plants depend on NEMA 7 or 9 enclosures to minimize explosion risks.

Materials Used in NEMA Enclosures

The material of the enclosure impacts its performance:

- Steel: Durable and cost-effective for indoor applications.

- Stainless Steel: Resistant to corrosion; best for food, beverage, or marine uses.

- Aluminum: Lightweight and rust-resistant; good for outdoor panels.

- Fiberglass/Polycarbonate: Non-conductive, corrosion-resistant, lightweight. Ideal for harsh environments.

Maintenance Tips for NEMA Enclosures

To maximize the lifespan of a NEMA enclosure:

- Regularly inspect for rust, cracks, or gasket wear.

- Ensure proper sealing after maintenance work.

- Clean enclosures in washdown areas with approved cleaning agents.

- Replace damaged enclosures promptly to avoid safety risks.

Conclusion

NEMA enclosures are essential for safeguarding electrical equipment in both indoor and outdoor environments. From basic NEMA 1 enclosures for office use to heavy-duty NEMA 4X and 6P enclosures for harsh outdoor or marine conditions, each type serves a specific purpose. Choosing the right one not only ensures equipment reliability but also guarantees safety and compliance with industry standards.

By understanding the differences between NEMA enclosure types and their uses, engineers, contractors, and facility managers can make informed decisions that protect their systems for years to come.