Introduction:

Welcome to the world of ducts! You may have heard the term thrown around in conversations about heating, ventilation, and air conditioning (HVAC) systems, but what exactly is a duct? Don’t worry; we’re here to shed some light on this essential component of modern buildings.

What is Duct?

In simple terms, a duct is a passageway or conduit used to move air, usually in a controlled manner. Ducts play a critical role in HVAC systems by dispersing hot or cold air across a structure. They serve as the circulatory system of your HVAC system, supplying conditioned air to every corner of your house or place of business.

Inside HVAC systems, ducts play a crucial role in moving air around. They are designed to deliver the air that’s needed for air conditioning, heating, and ventilation. These ducts also carry the ventilated air, which also serves as conduits for supply, return, and exhaust airflows. This enhances interior air quality and thermal comfort to a great extent.

A duct system, also known as ductwork, comprises thorough planning, sizing, optimization, detailing, and evaluation of pressure losses across the network. This comprehensive strategy, called duct design, guarantees the entire HVAC system’s efficacious operation.

Understanding Duct Systems

Duct systems function like complex networks of channels that direct air from the central heating or cooling unit to different rooms or zones within a structure. They are made up of a network of interconnecting registers, dampers, vents, and ducts. These components are interconnected and cooperate to keep interior temperatures as comfortable as possible.

What Are the Types of Ducts:

There are many duct types. Ducts are available in a variety of sizes, forms, and materials, each of which fulfills a distinct function and meets distinct HVAC needs. Here are a few typical duct types you may come across:

Sheet Metal Ducts:

One kind of ductwork frequently utilized in HVAC systems is sheet metal ducting. It is made of galvanized steel sheets shaped and assembled to form an air distribution network of ducts. These ducts are renowned for their robustness, resilience, and capacity to manage airflows under high pressure.

Sheet metal ducts can be manufactured in a variety of diameters and shapes to meet certain building layouts and HVAC requirements. Their dependability and long-term performance make them suitable for both commercial and domestic use.

Insulating sheet metal ducts is another way to increase energy efficiency. They can lessen heat gain or loss when air is being transmitted. HVAC specialists frequently select sheet metal ducts because of their adaptability and durability. During air transmission, they can lessen heat gain or loss. Because of its durability and versatility, sheet metal ducts are generally a preferred option among HVAC specialists. They can efficiently distribute air conditioning throughout buildings.

Flex Ducts:

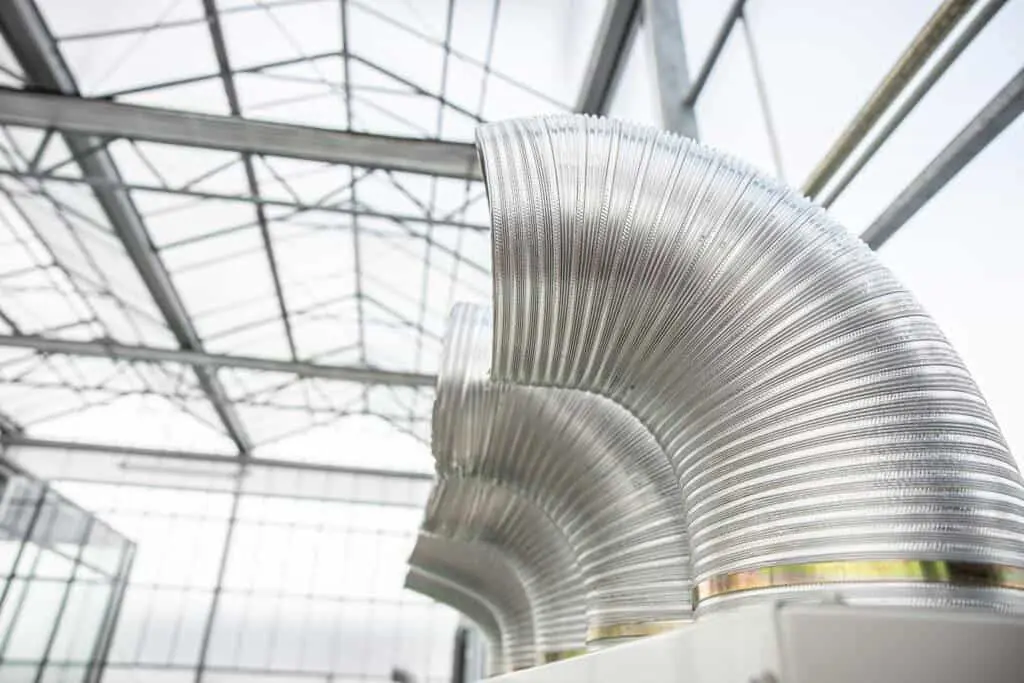

Flexible ducts, also known as flex ducts, are adaptable parts. They are frequently used in HVAC systems to distribute air. These flexible ducts, as their name implies, may bend and contour around obstructions and confined locations in which stiff ducts might not be useful.

A flexible inner core composed of plastic or wire helix is usually found inside flex ducts. The core is encased in insulation and protected by an outer jacket. Because of their structure, which offers flexibility and thermal insulation, flex ducts are suitable for a variety of settings, such as homes and businesses.

Flex ducts are frequently utilized in spaces with limited areas, like crawl spaces, attics, and spaces between floors. This is because of their flexibility. They are reasonably simple to install and need little effort to route around obstructions. To avoid kinks or other restrictions that can obstruct airflow, it’s crucial to make sure that the installation and support are done correctly.

Flex ducts may have more air resistance than rigid ducts despite being more versatile and simpler to install. If not installed and sized correctly, Flex ducts need proper inspection and maintenance at regular intervals to ensure optimal performance of the HVAC duct system.

Fiberglass Ducts:

Fiberglass insulation board is used in the construction of fiberglass ducting systems. They have good thermal qualities and are robust but lightweight. These ducts effectively insulate, which aids in the efficient maintenance of desirable interior temperatures. Because of its adaptability and energy efficiency, fiberglass ducts are frequently utilized in both business and residential environments.

One of fiberglass ducts’ main advantages is that they are resistant to corrosion, mold, and moisture, which allows them to be used in a variety of environmental settings. In comparison to other duct materials, they also require less maintenance and are very simple to install. Because fiberglass ducts don’t allow mold or mildew to grow inside the ducting, indoor air quality is improved.

Moreover, fiberglass ducts can be tailored to meet certain design specifications, guaranteeing a smooth integration with HVAC systems. Because of their resistance to high temperatures, fiberglass ducts are appropriate for situations where thermal insulation plays a critical role. Fiberglass ducts provide an economical and dependable option for optimal air distribution in HVAC systems.

Duct Board Ducts:

One form of ductwork that is frequently utilized in HVAC systems for both residential and commercial purposes is duct board ducting. They are built with insulated panels, which are composed of foam board or fiberglass. Because these panels are lightweight and strong, handling and installation are made simple. Excellent thermal insulation qualities of duct board ducts contribute to the preservation of comfortable interior temperatures and high energy efficiency in buildings. They are frequently used in scenarios where conventional sheet metal ductwork would not be feasible or when there is a shortage of space.

Cutting the panels to size, sealing the seams with specialist tape or mastic, and fastening them in place are the usual steps in the installation of duct board ducts. Despite its benefits, if duct board ducts are not adequately maintained or secured, they could be harmed by moisture or vermin. The long-term integrity and performance of duct board duct systems depend on routine maintenance and inspections.

PVC Ducts:

Polyvinyl chloride is a strong and adaptable thermoplastic material renowned for its resistance to moisture, chemicals, and corrosion. It is used to make PVC ducts, which are frequently utilized in a variety of commercial and industrial settings where aggressive materials or environmental risks exist.

Because of their smooth inside surface, PVC ducts reduce friction losses and promote efficient airflow, which enhances system efficiency overall. They come in a variety of sizes and designs to meet a range of ventilation needs, giving them flexibility in both design and installation.

PVC ducts are appropriate for both new installations and retrofit projects because they are lightweight and manageable. Many HVAC and industrial ventilation systems also favor them because of their affordability and low maintenance needs.

Overall, PVC ducts offer a reliable and long-lasting solution for conveying air and gasses in challenging environments, ensuring safe and efficient ventilation operations.

FAQs:

What is the duct system?

A building’s network of channels or passageways used for HVAC (heating, ventilation, and air conditioning) distribution of air is known as the duct system. It guarantees effective ventilation and controls temperature and air quality in different areas.

How do HVAC ducts work?

HVAC ducts distribute heated or cooled air throughout a building, regulated by a thermostat. The system draws air from the space, passes it through a heat exchanger or cooling coil, then pushes it back through the ducts to maintain desired temperatures and air quality.

What is the best ductwork for HVAC?

Budget, space restrictions, and efficiency objectives are some of the criteria that commonly determine which ductwork is best for the HVAC system. On the other hand, high-quality insulated flexible ductwork composed of polyester or fiberglass typically provides good airflow, energy efficiency, and ease of installation.

What do you mean by ductwork?

Ductwork is a network of ducts that HVAC (heating, ventilation, and air conditioning) systems utilize to transport air throughout a building. Ductwork provides adequate ventilation and climate control. It is made up of pipes or channels that transport warm or cool air from the central unit to other rooms or spaces.

Final Verdict:

Ducts are essential parts of HVAC systems that guarantee indoor comfort and air purity. Ducts quietly operate in the background to provide conditioned air where you need it, whether you’re lounging by the fireplace in the winter or taking in a cool breeze in the summer.

Thus, the next time you feel a light breeze coming from the vents above or set the thermostat, stop to admire the simple duct—an unsung hero of contemporary comfort and convenience.